When you purchase stainless steel, you soon realize it is not only one steel, but wide variety of steels. Traditionally stainless products were named with number codes. Now understanding the properties is easier with descriptive names.

Steel is defined stainless if it contains more than 10.5% chromium, while other alloying materials define the properties of stainless steel. Even the best quality stainless may rust if the grade is not suitable for the chosen environment.

Traditionally stainless products were named with number codes like “304” or “1.4301”, how do you know which is suitable for your application?

Identified by performance

Outokumpu was the first company to regroup its products by performance in May 2015. With Outokumpu’s new categorization system, you can review stainless steel products by performance characteristics (strength, corrosion resistance, hardness) instead of by microstructure (austenitic, ferritic, martensitic, duplex). The categorization makes it easier to explore Outokumpu’s product range and compare products with similar behavior. Although the product portfolio has been restructured, chemical and mechanical properties of existing grades remain unchanged.

Nine product ranges are divided into two families: Classic and Pro.

Classic family – basic grades

The Classic family contains three basic, all-purpose grades that are identified by level of corrosion resistance.

MODA for mildly corrosive environments

Outokumpu Moda products are designed for mildly corrosive environments, often seen in household equipment indoors. All of these products are ferritics, meaning that they do not contain nickel, which makes their price level less volatile.

CORE for corrosive environments

Outokumpu Core is intended for corrosive environments and the most common stainless steel Core 304/4301 is found in this range. This is the true multipurpose grade for indoor applications and even mild conditions outdoors. Products made out of Core 4622 are particularly good for deep pots and pans.

SUPRA for highly corrosive environments

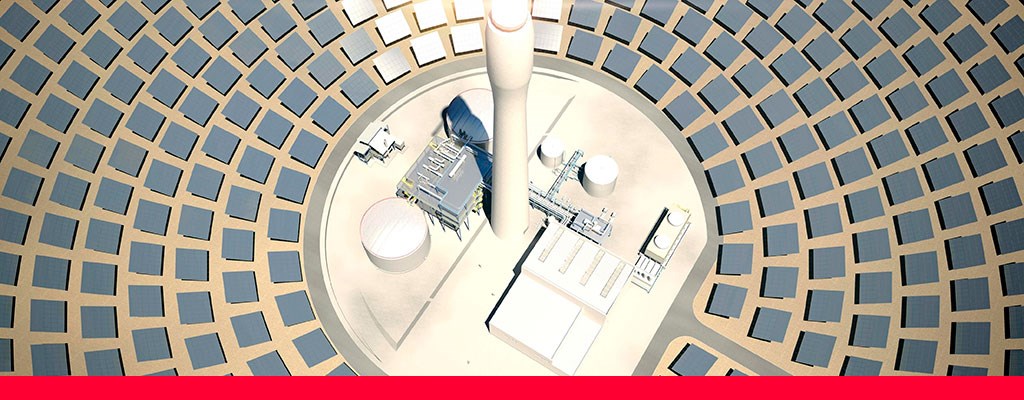

Outokumpu Supra products are designed for applications that demand higher than normal corrosion resistance. Outokumpu’s innovation, high-chromium Supra 316plus belongs to this range. These grades are ideal for a wide range of uses, such as facades, process industries, storage and cooling tanks, heat exchangers and tubing.

Specialized, demanding needs served by Pro

For uniquely demanding projects, consider the Outokumpu Pro family: Forta, Ultra, Dura, Therma, Prodec and Deco.

FORTA for high-strength with cost efficiency

Outokumpu Forta combines high-strength with cost efficiency. This range includes duplex stainless steels that are often used in demanding bridge applications. The lightweight H-series grades can be found for example in various car parts: they are light, but in the case of a collision they absorb the energy of the crash.

ULTRA for extremely corrosive environments

Outokumpu Ultra products are designed for extremely corrosive environments in the process industry. In this range you can find products that were referred to as highly alloyed and super austenitics.

DURA for high hardness

Outokumpu Dura products provide exceptional hardness and strength. This range’s product are a highly competitive alternative to carbon steel. Dura products are used in everything from high quality kitchen knives and surgical scalpels to machine parts that and aircraft landing gears.

THERMA for high temperatures

Outokumpu Therma is designed for applications with service temperatures above 550º Celsius (1020º F). Therma’s ferritic products are typically used in chemical, power and metalworking industries, as well as in furnace technology.

PRODEC for longer tool life

Outokumpu Prodec products are optimized for improved machinability with longer tool life and enhanced quality. This property lowers total cost for machined parts with better final surface and dimensional tolerances.

DECO for special surfaces

The Outokumpu Deco range boasts special surfaces. These surface finishes can be applied to various steel ranges, and they give the stainless its unique looks. An example from this range is Deco Laser, the surface finish developed for One World Trade Center in NYC. The Deco range’s products may be used indoors and outdoors. Uses for Deco are limited only by imagination.

What is the right range and grade for you?

Your application plays the most important role in selecting the stainless steel grade. Where is it located geographically? Is the application indoors or outdoors? Is there contact with chemicals or exposure to extreme heat?

Have a question? Our team of experts is more than willing to assist you!

If you are a newcomer to the world of stainless steel, it is best to talk with an Outokumpu sales representative or technical customer representative who can give guidance regarding which grade to choose. Even if you had been using stainless for a while, it is good to review whether you are actually using the best grade for the application. As you can see, there is a wide variety in the tool box.