Shaping the Future: Unveiling the Rise in Demand for Sustainable Stainless Steel and Its Commercial Potential

A shift towards sustainability

The global steel industry, traditionally a significant contributor to carbon emissions, is now at a crossroads. As climate change and urbanization continue to reshape the world, the demand for low-emission, sustainable materials has never been greater. Stainless steel, with its unique properties and long lifecycle, is positioned as a key material in this transition.

Dr. Menzel emphasized the strategic importance of stainless steel in various emerging industries, particularly in the context of the energy transition towards a hydrogen-based economy.

"The production and storage of hydrogen, especially for electrolysis, demand a significant amount of stainless steel. Robust stainless steel tubes and tanks are crucial for safe hydrogen transportation, making it an essential infrastructure material for the hydrogen industry," he noted.

The medical sector also represents a burgeoning market for stainless steel. With an aging population and increasing demand for medical devices, the use of stainless steel in med-tech appliances is expected to surge.

"Stainless steel's durability and resistance to corrosion make it ideal for medical applications, where hygiene and longevity are paramount," Dr. Menzel explained.

Outokumpu's leadership in sustainable production

Outokumpu, a global leader in stainless steel production, has long recognized the importance of sustainability. The company has made significant strides in reducing its carbon footprint and promoting circularity in its operations.

"Our production process is unique," Dr. Menzel stated. "We use fully electric production methods based on electric arc furnace technology, and 95% of our raw materials are recycled. This positions us at the center of the circular economy."

Outokumpu’s sustainability strategy is built on four pillars: reuse, reduce, renewable energy, and transparency. The company's commitment to the circular economy is evident in its use of recycled materials, with a target of maintaining at least 90% recycled content in its production processes. Energy efficiency is another critical focus, with Outokumpu aiming to increase its energy efficiency by 8% by the end of 2024.

Setting new standards with Circle Green

One of the most significant achievements highlighted in Dr. Menzel’s keynote was the introduction of Outokumpu's "Circle Green" stainless steel. This product represents a breakthrough in low-carbon stainless steel, boasting a 93% lower carbon footprint than the industry average.

"For Circle Green, we rely on 100% low-carbon electricity and carefully selected raw materials," Dr. Menzel shared.

The environmental impact of conventional stainless steel production is significant, with an industry average of 7 tons of CO2 emitted per ton of steel produced. In contrast, Circle Green emits just 0.5 tons of CO2 per ton of produced steel

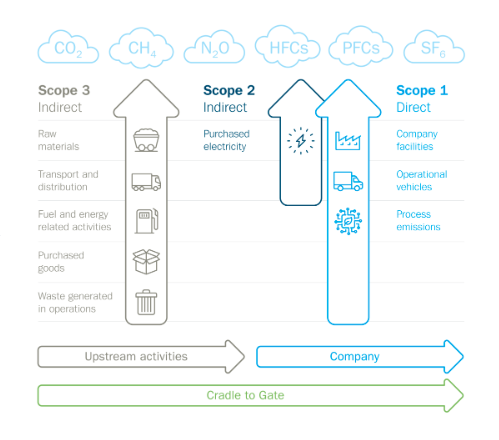

"This is the first time in history that we have been able to produce more steel than CO2," Dr. Menzel proudly stated. "If we calculated only scope 1 and scope 2 emissions, we could bring emissions close to zero, but our approach includes scope 3 emissions to provide a complete and honest carbon footprint."

The economic potential of green steel

The transition to green steel is not just an environmental imperative—it also presents significant commercial opportunities. However, the question remains: Are customers willing to pay a premium for sustainable steel? According to Dr. Menzel, the answer is increasingly yes, particularly in Europe.

"The European market is advanced, and we see more customers requesting Circle Green products despite the green premium in pricing," he said.

Dr. Menzel outlined three critical factors for capturing the green premium in the market. First, transparency is key. Companies must account for all three scopes of emissions – direct (scope 1), indirect (scope 2), and value chain (scope 3) – to justify the premium.

Second, having a verified product carbon footprint is essential. Customers need to see clear, quantifiable reductions in carbon emissions. Third, while carbon offsetting is an option, Dr. Menzel emphasized that it should not be the primary strategy.

"Offsetting is often questionable. Instead, we focus on actual emission reductions," he explained.

A call for industry-wide change

While Outokumpu has set the standard for sustainable steel production, Dr. Menzel acknowledged that the industry still has a long way to go. The global stainless steel industry's average carbon footprint is around 7 tons of CO2 per ton of steel, with Asian producers, particularly in China and Indonesia, emitting as much as 8.8 tons. In comparison, Outokumpu's European peers have an estimated average footprint of 2.9 tons, but even that pales in comparison to Outokumpu's 1.5 tons.

"Why should a responsible consumer in Europe use steel from Asia when it has such a high carbon footprint?" Dr. Menzel asked.

The answer lies between pricing pressure but also in a lack of awareness and transparency.

"We need to push for more transparency across the value chain and educate customers on the environmental impact of their choices. This goes even further than the carbon footprint and should include social aspects where the difference between Europe and Asia can be huge."

The future of stainless steel

As the keynote drew to a close, Dr. Menzel reflected on the future of stainless steel and its role in the green industrial transition.

"Stainless steel offers unique properties that other materials like carbon steel or aluminum cannot match. Its resistance to corrosion gives it a product lifecycle of 100 years or more, making it an incredibly sustainable choice," he said.

The future of the stainless steel industry, according to Dr. Menzel, hinges on a holistic approach to sustainability. This includes not only reducing emissions and increasing recycled content but also designing products for longevity and minimal maintenance.

"A holistic approach to product design is crucial for a resource-efficient society," he concluded.

Conclusion

The rise in demand for sustainable stainless steel is not just a trend—it is a fundamental shift in the way industries operate. As Dr. Menzel’s keynote highlighted, the transition to low-emission steel is both an environmental necessity and a significant commercial opportunity. With its innovative Circle Green product and commitment to transparency and sustainability, Outokumpu is leading the charge in this green industrial revolution.

However, the road ahead is challenging. The industry must overcome hurdles related to pricing, transparency, and global competition. But with strong partnerships and a clear focus on sustainability, the future of stainless steel looks bright, promising a world where low emission steel becomes the norm rather than the exception.

Outokumpu Circle Green®

The new standard for sustainable stainless steel with up to 93% lower carbon footprint.