The production of stainless steel plays an unexpected role in industries ranging from road construction to agriculture. Through its advanced processes, Outokumpu can utilize the by-products generated at its production sites to suit new purposes. Because of this, natural resources are preserved and quantities of waste are reduced.

As previously written in What if waste was turned into profit article, Outokumpu is a pioneer in recycling materials resulting from stainless steel production. The Group’s manufacturing processes are highly developed to utilize valuable elements from various material streams.

Using by-products enables Outokumpu to minimize the use of virgin raw materials and reduce quantities of waste. If the features of the material are suitable, Outokumpu aims to utilize even the slightest side streams. Whether the side stream materials are considered as a by-product or waste depends on the country’s circumstances and regulations. For example in Sweden, most of the slag has to be landfilled.

This article explains more specifically what can be made from by-products and what benefits there are to using side stream material.

From natural stone to soil conditioner

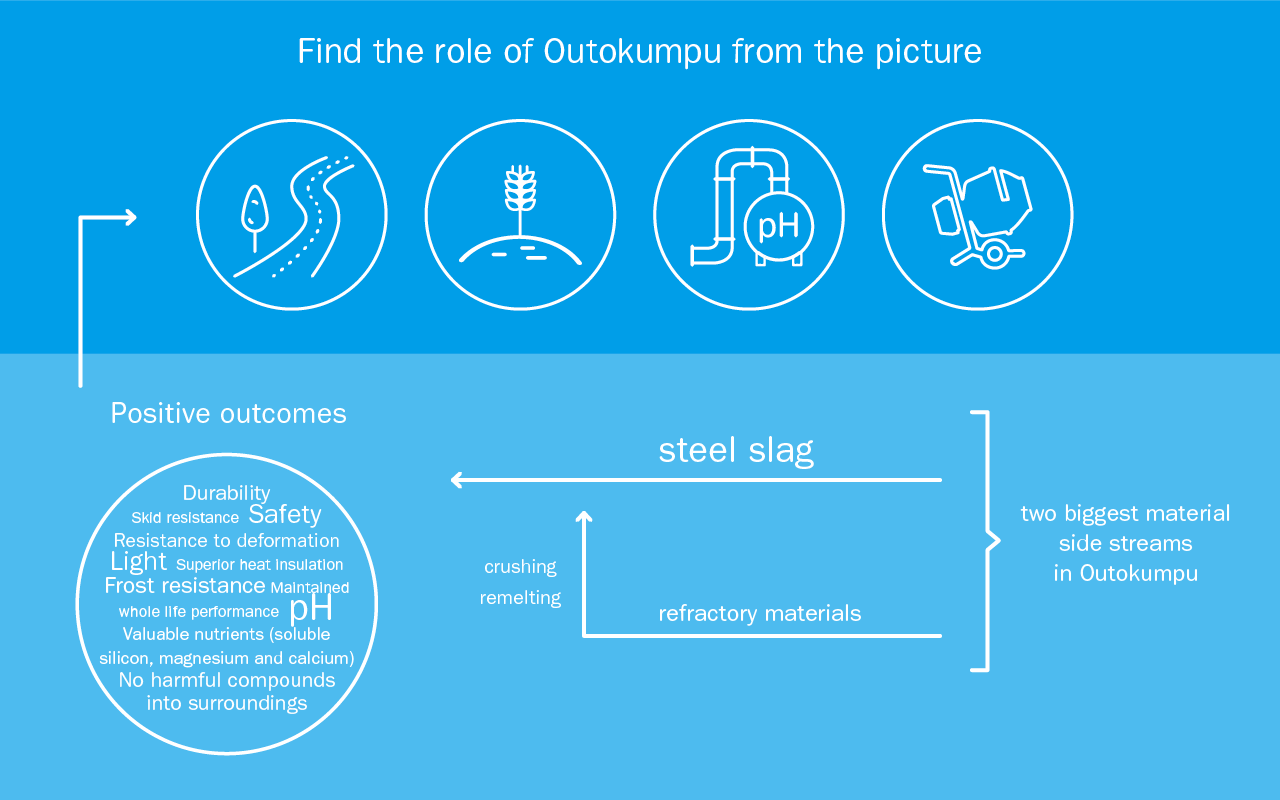

One example of side stream utilization is the process of transforming metal processing slag into products. In hot liquid metal making, slag is an essential material since it protects the metal against oxidization and heat loss. For this purpose, certain natural minerals such as limestone are added to the process as slag formers. Slag from Outokumpu’s stainless steel processing is used to replace natural stone material in road construction and neutralization in industrial processes. In the United States, Outokumpu’s melt shop in Alabama produces slag that can be used as a soil conditioner and liming agent in agriculture. In Northern Finland, Outokumpu’s slag by-products have been used for road construction and other similar purposes for decades. During the last two years these slag by-products have been fully used. There are still, however, other side stream materials such as sludges that need to be landfilled since their features prevent the utilization for other purposes. Aside from slag, another significant by-product is used refractory material from melt shops. This material is being repurposed in the steel making process as a slag conditioner. Since it also ends up in the slag, it is effectively used three times: as refractory brick, as a substitute for lime for the formation of slag, and as a substitute for road stone in asphalt production.

Preserving natural resources

When slag is not landfilled or disposed of as waste, it has great environmental benefits. Using slag as a substitute for a natural resource reduces the use of virgin raw materials. This also eases the pressure on communities and ecosystems, and preserves the natural features of the area. In road construction, stainless steel slag is an excellent material to use because an asphalt containing slag increases the durability of road surface. This makes the road safer and longer lasting, since there is less need for road repairs. Other features that benefit the road user include good grip values, skid resistance and reduced risk of aquaplaning. For example in Sheffield, the main part of Outokumpu’s stainless steel slag is used for asphalt. In Northern Finland, over 20 million cubic meters worth of virgin materials such as natural gravel have been saved throughout the years just by using slag from Outokumpu’s ferrochrome production for road building. This is equivalent to about 18 Chrysler Buildings. The ferrochrome slag has been an important by-product in the area for decades. In wet and cold climate insulation, the properties of ferrochrome slag are superior compared to those of natural stone and therefore the road structure can be built lighter. The materials also do not release harmful compounds into their surroundings. In addition to all the environmental benefits, using side stream material also saves money, since there is no need for expensive landfill costs. It is also less expensive to buy for Outokumpu’s customers. Slag, for example, can be purchased locally for roughly 60% of the cost of lime.